-40%

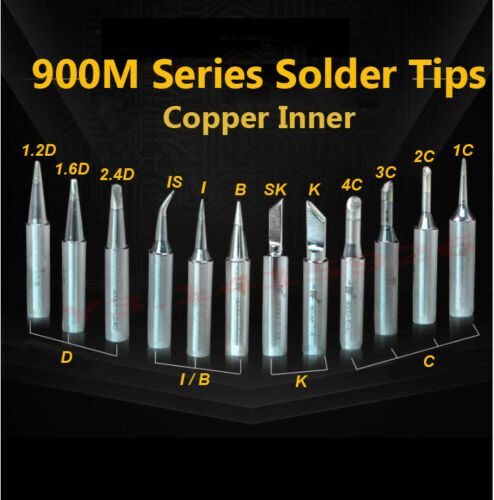

Quality 900M soldering iron tips set For Weller soldering station tools

$ 3.8

- Description

- Size Guide

Description

Specification:Brand new

Type: Soldering Iron Tip

Material:Copper

Temperature Range: 200°~480°

Life : no less than 50,000 welding spots

Suitable for standard welding tips of ATTEN high frequency soldering station, suitable for Hakko

*900M series, Outer DIA 6.3mm, Inner DIA 4mm

*900L series, Outer DIA 8.5MM, Inner DIA 4.1mm

*This list is for 900M series.

*Standerd soldering tips suitable for most of 888,913,907,935, 936,

937,938, 969, 980

soldering station, suitable for most of Hakko, standard

soldering station iron.

Also fit Duratech TS-1380

warm prompt

1, The iron head should be used within the normal temperature range as far as possible to avoid low temperature welding, which can extend the service life of the iron head

2, the iron head welding for a period of time, the surface will appear oxide layer, it is recommended to use professional tools to remove, otherwise there will be the phenomenon of do not eat tin, iron head do not eat tin, 80% of the factors and your usual use habits.

3, do not dry burning iron head, otherwise it will affect the service life.

Maintenance of molten iron head

1,B

efore Welding Work

must first wet the cleaning sponge,

and then squeeze out the excess water, so as to make the iron head to get the best cleaning effect.

If you use a non-wet cleaning sponge,

Will make the iron head damaged and lead to no tin.

2.

When the soldering iron tip was used for the first time

Pay attention to check the temperature of the tip, when the temperature is just enough to melt the tin wire, a layer of tin is placed on the key of the tip, and then the temperature is raised to the required temperature.

Remember that the tip should be protected by a layer of tin for a long time to achieve the best welding function.

3. After welding

First set the temperature to about 250℃, then clean the los iron head, and add a new layer of tin for protection.

(If you are using an uncontrolled welding table, cut off the power supply and let the temperature of the molten iron drop slightly before applying tin.)