-40%

Digital Soldering Iron Station Temperature Controller DIY Kits For HAKKO T12

$ 6.33

- Description

- Size Guide

Description

Digital Soldering Iron Station Temperature Controller DIY Kits For HAKKO T12Note: 1: If you choose Color LED, it will come with A soldering iron + a aluminum shell + a power unit

2: We have the installation video of this DIY kit, if you want it, please contact us by ebay message

The Package Listing as the above photo shows all diy kit, include the shell and power supply, the power supply

match the shell, not need to change that to fit the shell.(But if you choose "

24V 4A Power only

", the package

only come with a power, not the DIY kits)

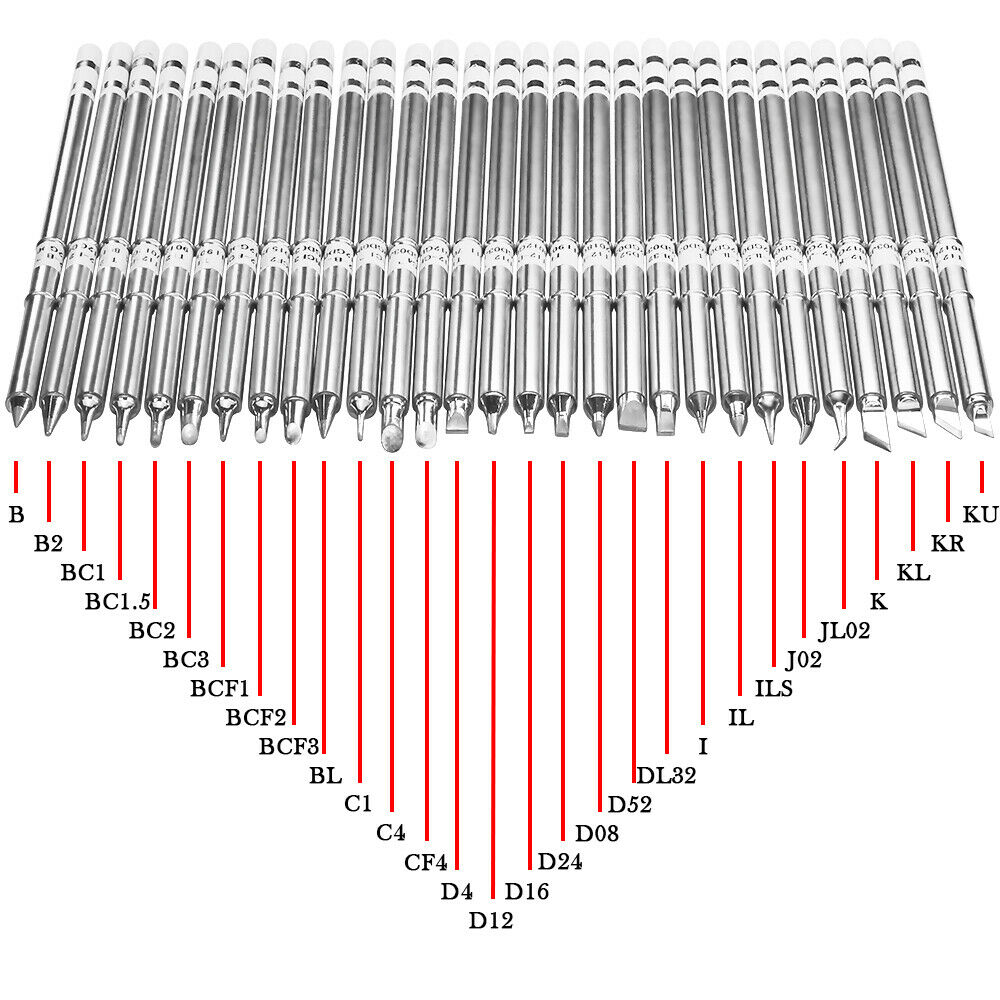

We will send T12 soldering Tip "T12-K" , if you want other tips in the following photo, you can left the message

for us,we will send that for you(instead of the standard T12-K tip), if you want more extra tips, you can add the tips

you need to your cart at the top of this product description

Attention: Before test machine, be sure to confirm the correct line, positive and negaitve, otherwise

the heating core must be heated to red and burn, you can see the following English manual !

This product is a DIY Kits, buyers need to own welding. DIY risk, novice buy carefully, If it is man-made damage, we do not

assume responsibility, Thanks for your understand.

This item can use in T12 T2 T13 T15 heating core, auto sleep, ball bearing vibration. Blue light white word

DIY Kits Description:

1. T12 digital temperature controller(vibration switch +LED +Knob)

input voltage: 12V-24V

Temperature adjustment range: 200℃~450℃ ,Maximum Power: 75W

2. T12 soldering Tip shape-K

3. T2 / T12 handle(907 handle conversion)

4. T2/ T12 inner tube bracket kits

5. Silicone 5 core cable, cable length 110cm/3.6ft

6. Soldering station iron 5 core aviation plug

7. Flux

8. The solder

9. Aluminum shell

10. 220V to24V 4.5A new power switching transformer

11. Other cable/accessories (as the first picture show)

Controller parameter setting mode:

(The default has been set, no special requirements, please do not set up a random)

Press and hold the encoder button does not move → start → enter the parameter settings mode:

There are 12 menus available for setup,P00,P01,P02,P03,P04,P05,P06,P07,P08,P09,P10,P11.The digital display menu is 1.5 seconds,and then automatically

displays the corresponding parameters of this menu,at the same time rotate left encoder is reduced,right is increase,Press it and automatically save the currently

set parameters.And then display the next menu for 1.5 seconds, and then display the corresponding parameters of this menu, and so on. When all parameters are

set to automatically enter the normal heating mode.

Because each set a parameter to save once, so you can shut down at any time without having to set all the parameters

(such as you just want to set P01, set P01 after you can shut down and then boot into normal mode)

Menu item:

P00: restore the default parameters (0 or 1, the default value of 0,0 for not recovering, 1 for the recovery)

P01: Operational amplifier gain (200 to 350 times, step 1, default 230)

P02: Operational amplifier offset voltage (0 ~ 250mV, step 2, the default value of 100, refers to the tip to keep the room temperature operational amplifier inherent output voltage, according to my measurement this voltage varies greatly with temperature, different magnification Not the same, the higher the magnification, if you do not measure, please keep the default value)

P03: thermocouple ℃ / mV data (30 ~ 50, step 1, the default value of 41, refers to the thermocouple need to temperature how much voltage was increased by

1mV, according to the type of thermocouple self-calculation, if you do not understand, please keep Defaults)

P04: temperature adjustment step (0,1,2,5,10 degrees optional, 0 can lock the soldering iron temperature)

P05: sleep time (how long don’t not move into sleep) (0 ~ 60 minutes, step 1, 0 is to forbidden the sleep function)

P06: Shutdown time (0 ~ 180 minutes, 0 ~ 30 step 1,30 ~ 180 step 10, 0 is forbidden shutdown function)

P07: temperature correction (+20 degrees, step 1) (due to NTC resistance in the chassis, the soldering station heat will lead to the detection of NTC temperature higher than room temperature, resulting in high temperature compensation of the thermocouple, soldering iron temperature is not accurate,or other causes the temperature is not accurate.If you set the other parameters are correct value but the temperature is still high or low, you can use this parameter correction.For

example, to detect the displayed soldering iron temperature is 20 degrees higher than the actual value of this

parameter Set to 20)

P08: wake mode (0,1, 0 in the shutdown mode can be rotated the encoder and also can shake the handle to wake up, 1 can only rotate the encoder wake up (Note: press the encoder can not wake up, can only rotate) )

P09: temperature increase mode to increase the temperature to adjustable (20 degrees to 100 degrees adjustable, adjust the pace of 10 degrees)

P10: temperature to increase the duration to adjustable (adjustment range of 10 seconds to 250 seconds, adjust the step 5 seconds)

P11: Parameter setting mode Auto save parameter and return to heating mode Function to active time adjustable (range 4 seconds to 60 seconds)

Installed Note:

1. Strictly reference shop tutorials, well insulated and grounded against static electricity.

2. Before power test, carefully check the wiring is correct, whether Weld and short, full power test machine after confirmation.

3. connect 12-24V DC, if received more than 20V power supply,2017 new style product don't need to remove anything!

4. When you configure the power supply voltage and current requirements themselves refer to the following table:

Power (third column) is determined by the voltage (first column), as long as the current reaches the minimum current (second column).

Measuring Machine normal, lights and display status:

1. Unplugged T12 tip, turn the light flashed off, show SER, 1 seconds after the display 500.

2. T12 plug tip, boot light uniform flashing, indicating rapid heating from room temperature generally show the set temperature to rise, approaching the set temperature, strobe lights. Indicator is not flashing or intermittent flashes, indicating that the tip temperature reaches the set temperature or alternating temperature compensation.

When measuring machines on display digital bounce questions:

Because with the new T12 tip, the tip inside the heater did not burnt, it will be just a little jump start with warm, generally do not need special treatment, the natural use of 1-2 days basically not bounce up. If you need effective immediately, the general recommendations of the temperature to 350 ?-380 ?while heating to the point of tin iron head, burning off after 4-5 minutes, until the tip to cool before you can reboot! (1 no action can be repeated 2-3 times)