-40%

200 series Quality soldering iron tips kit For QUICK High-Frequency Soldering

$ 7.75

- Description

- Size Guide

Description

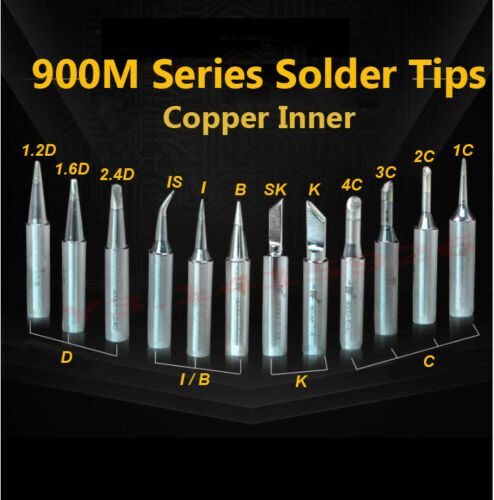

For ATTEN / QUICK High-Frequency Soldering Station solder Iron Tip Station solder Iron Tip 200seriesRound head B tsui features:B shape slender, suitable for spot welding in the environment of high and low components, easy to use and flexible.

Application: general welding, suitable for all kinds of solder joints

Horseshoe head C tsui

features: Weld the inclined surface of the soldering iron head

Application: used for components with thick terminals, large tin content and large area

Flat head D tip

features: TYPE D is flat head, flat heat area is large。

Application: used for components with thick terminals, large tin content and large area

Special tip I tip features: the tip of type I soldering iron tip is small。

Application: used for narrow and fine welding of solder surface. Also used for correcting the tin bridge produced when welding chip.

Features: the tip of the J soldering tip is small

Application: used for narrow and fine welding of solder surface. Also used for correcting the tin bridge produced when welding chip.

K tip features: K type uses knife part for welding, can be vertical welding or pull-welding welding, belongs to multi-purpose soldering head.

Application: used in power supply grounding parts of the components, correction tin bridge and other welding.

Category: 200 Series

Excellent thermal conductivity, special iron plating process, corrosion, oxidation resistance, long life.

Strong wettability, ductility, easy to tin, solder joints round;

Scientific and rigorous chemical inspection, inductance balance, stable quality.

Lead-free materials, lead-free environment manufacturing, ensure to meet the requirements of lead-free process.

Maintenance of the soldering iron head:

1. Before welding.

The sponge must be moistened first and then squeezed to dry the excess water.

Only in this way can the molten iron head get the best cleaning effect.

If you use a non-wet cleaning sponge, it will damage the iron head and lead to no tin.

2. try to use low temperature welding high temperature will accelerate the oxidation of the iron head, reduce the life of the iron head.

If the head temperature exceeds 470℃, it oxidizes twice as fast as 380.

3. do not put too much pressure on the welding, do not put too much pressure, otherwise the iron head will be damaged and deformed.

Heat can be transferred as long as the tip of the soldering iron is in full contact with the solder joint.

In addition, the selection of the right iron head can also help heat transfer.

4. Always keep the tin on the tip of the iron

This can reduce the oxidation of the iron head, make the iron head more durable. After use, the temperature of the iron head should be reduced slightly before adding new solder, so that the tinning layer has a better anti-oxidation effect.

5. Keep the tip of the soldering iron clean and clean the oxide immediately

If there is black oxide on the iron head, the iron head may not be tin, and it must be cleaned immediately. When cleaning, first turn the temperature of the iron head to about 250℃, and then clean the iron head with a cleaning sponge, and then apply tin. Repeat until the oxide is removed.

6. The flux with low activity and high activity or strong corrosion will accelerate the corrosion of the soldering iron head when heated, so the flux with low corrosion should be selected.

Note: Do not use sandpaper or hard objects to clean the tip of the soldering iron.